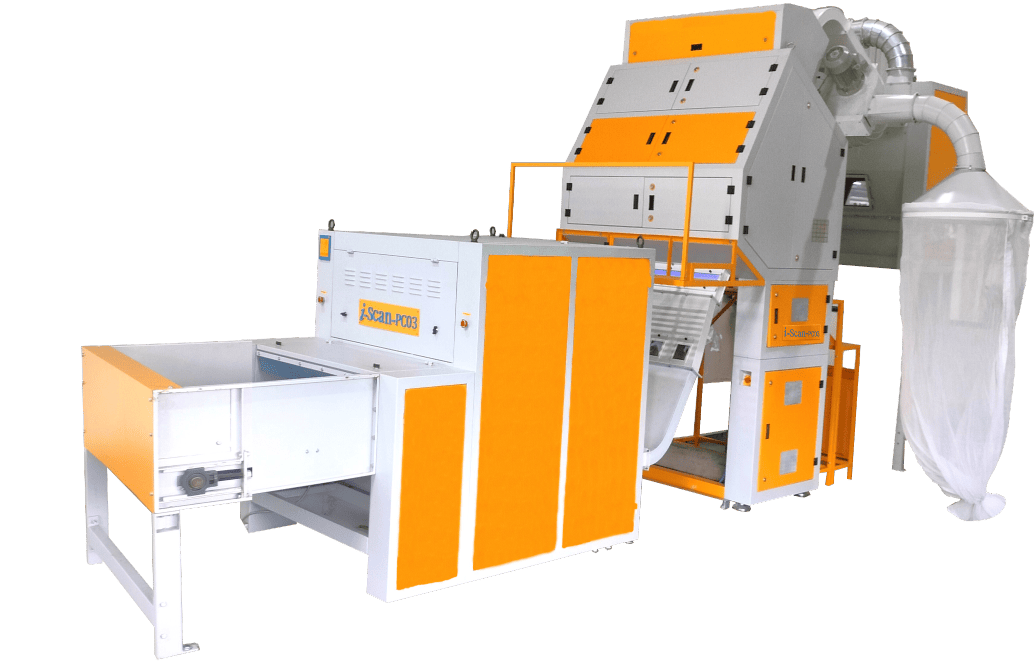

In today's spinning industry, two critical challenges stand out: Rising cost of labour and the significant loss of good fibers during contamination removal process. In continuation of pursuing the vision of creating value for customers, Nestling proudly introduces the i-Scan-PC03: The Recovery plant This customer-centric, customised, state-of-the-art experience redefines how mills recover the good fibers from ejected cotton, enhancing efficiency and profitability

- Contamination detected and ejected from the contamination sorter carries good opened fibres along with it.

- Huge manpower is being deployed to segregate good fibres from contamination (≈ 25–40 kg / person / day).

- Expected efficiency of manual segregation is around 40–50% and is not consistent.

- High possibility of mixing contamination into fresh cotton due to improper manual segregation of ejected cotton.

- A mechanized process is therefore required to segregate contamination from ejected cotton efficiently.

WORKING PRINCIPLE

Ejected cotton with contamination is processed for mild pre-opening. The opener speeds can be controlled by inverter according to the requirements.

Inverter controlled feeding system ensures regulated feed of ejected cotton for better opening of fibres.

During the mild opening, trash present in the fibres falls down and opened fibres with contamination pass-through high resolution scanning elements where contamination (Colour and White PP) will be detected, ejected and collected separately

Good fibres are sucked through fibre separator and gets dropped. From where it is taken forward for baling or further process.

Expected cleaning efficiency of contamination is around 80 to 90%* and above, at the production of 50kg / hour.

- Production capacity: 50 to 100 kg / hour

- Installed power: 9.0 KW (max)

- Pneumatic air usage: 15 CFM (max)

THE COMMITTED EXPERIENCE:

- Recovering the good fibres without any damages of it's Qualities.

- Consistent in cleaning of contaminations and other foreign matters like trash, seed coats etc...

- Fully automated process, easy to operate and maintain.

- Huge manpower savings and an attractive ROI.

- The spirit of indigenous innovation.

- Effective after sales-service with spare parts supports through our nationwide service network.